Special oil-free rotary lobe pump reduces oil contamination risk in food production

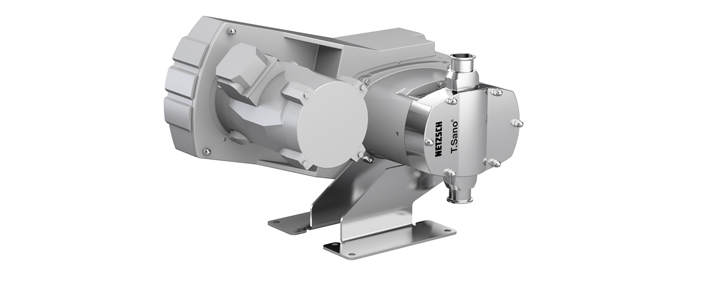

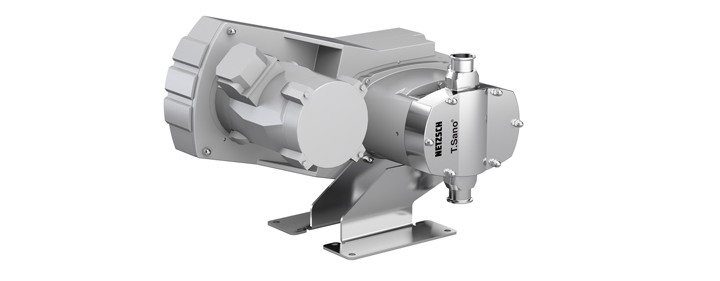

A European chocolate producer decided to use a hygienically safe unit from NETZSCH Pumpen & Systeme GmbH in Germany for the production of almond-nougat paste. The abrasion-free all-metal version of the T.Sano® rotary lobe pump with its lubricating oil free drive minimizes the risk of contamination and ensures food safety. The design of the EHEDG-compliant pump has been recently revised and is now characterised by a smooth housing design, which makes cleaning easier than ever before as it avoids all unnecessary sharp edges or crevices. A certification according to 3-A Sanitary Standards is planned.

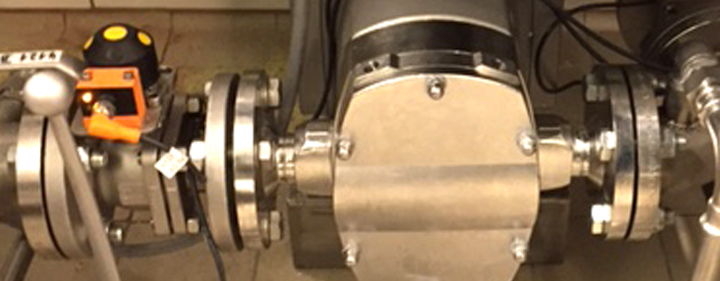

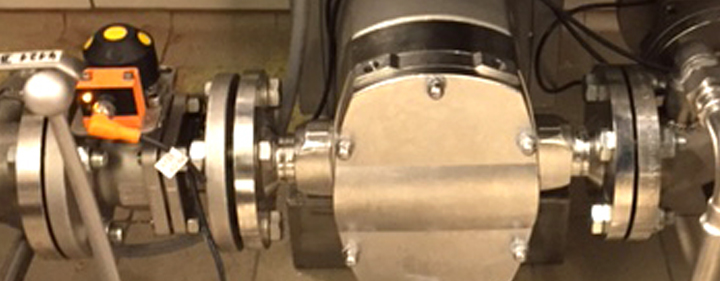

The rotary lobe pump is equipped with an oil-free double-sided belt drive. As the direction of flow changes it is used in the first step to transport the nougat paste from the receiver container to the fine grinder and to fill it. Then it pumps the finished paste to the receiver container of the production line. It pumps approximately 600kg/h at a counter-pressure of 3.4 bar and a temperature of 45° C. The producer is very satisfied with the pumping capacity and the reliability of the pump. The easy cleanability of the pump supports the smooth process flow and the high quality of the medium is no longer subject to any risk at this stage.

A European chocolate producer decided to use a hygienically safe unit from NETZSCH Pumpen & Systeme GmbH, for almond-nougat paste production to minimise the risk of contamination.

In a first step, the unit is used to transport the nougat paste from the receiver container to the fine grinder and to fill it. In the second step, the pump is used for circulation until the product reaches the desired grinding degree. Then it pumps the finished paste to the receiver container of the production line.

Instead of the usual, complex synchronisation gearing, an oil-free toothed belt drive transfers the torque from the motor to the rotary lobes while synchronising the rotation of the rotary lobes in the case of this design.

The design of the unit has just been revised in 2017 to make the EHEDG-certified pump even more hygienic: The housing of the T.Sano® is completely smooth now, so it is easy to clean.

The rotary lobe pump is equipped with an oil-free double-sided belt drive. As the direction of flow changes with the it is used to transport the nougat paste from the receiver container to the fine grinder and to fill it. In the second step, the pump is used for circulation until the product reaches the desired grinding degree. Then it pumps the finished paste to the receiver container of the production line. It pumps approximately 600kg/h at a counter-pressure of 3.4 bar and a temperature of 45°. The producer is very satisfied with the pumping capacity and the reliability of the pump. The easy cleanability of the pump supports the smooth process flow and the high quality of the medium is no longer subject to any risk at this stage.

A European chocolate producer decided to use a hygienically safe unit from NETZSCH Pumpen & Systeme GmbH, for almond-nougat paste production to minimise the risk of contamination.

In a first step, the unit is used to transport the nougat paste from the receiver container to the fine grinder and to fill it. In the second step, the pump is used for circulation until the product reaches the desired grinding degree. Then it pumps the finished paste to the receiver container of the production line.

Instead of the usual, complex synchronisation gearing, an oil-free toothed belt drive transfers the torque from the motor to the rotary lobes while synchronising the rotation of the rotary lobes in the case of this design.

The design of the unit has just been revised in 2017 to make the EHEDG-certified pump even more hygienic: The housing of the T.Sano® is completely smooth now, so it is easy to clean.

For more than 60 years, NETZSCH Pumps & Systems has served markets worldwide with NEMO® progressing cavity pumps, TORNADO® rotary lobe pumps, NOTOS® screw pumps, grinding machines, barrel emptying systems, dosing systems and accessories, providing customised, sophisticated solutions for applications in every type of industry. With a workforce of over 2,000 and a turnover of more than 245 million euros (2016 financial year), NETZSCH Pumps & Systems is the largest business unit with the highest turnover in the NETZSCH Group, alongside NETZSCH Analysing & Testing and NETZSCH Grinding & Dispersing.

NETZSCH Pumpen & Systeme GmbH

Geretsrieder Straße 1 / 84478 Waldkraiburg / Germany

Tel.: +49 8638 63-2356 / Fax: +49 8638 63-92356

pr.nps@netzsch.com / www.netzsch.com