The Acemal Company is specialized in the construction of industrial equipments for cookies industries and more specifically for waffles industries since 1965. Our qualified team takes charge of the complete realisation of the equipments from the conception to the moving off. The numerous technical innovations allow us to respect the confines linked to the different processes. Our large experience in the field of the waffle equipment and our flexibility allow us to offer made to measure equipments for our customers. We work in cooperation with them in order to adapt our products to their needs and demands. The attention and the care given to the carrying out of the installations have, over decades, earned us the confidence of our customers. Our company offers a wide range of equipments from individual module to complete production line.

Food trays and baking molds made from Genuine Vegetable parchment are biodegradable and home compostable.

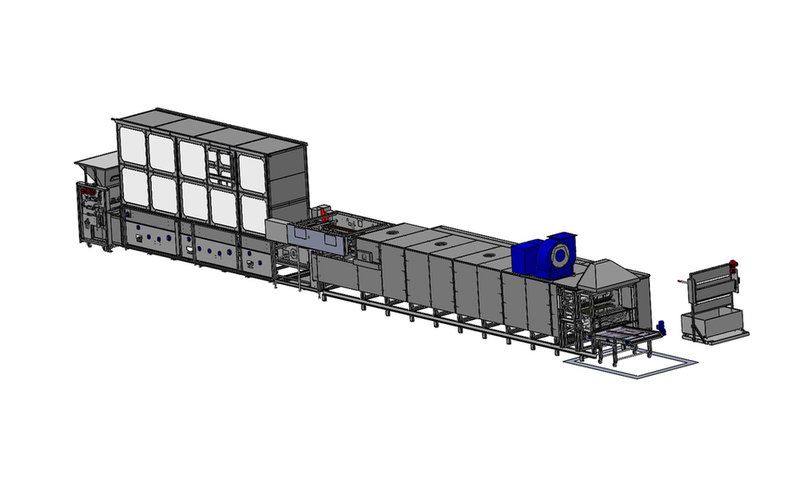

Automatic lines

The automatic line allows an automatic cooking for all kind of pastry. Our equipments deal with all of the industry’s stages from the pastry to the cooling of the product. Our production lines are made of the following elements:

Automatic line for Liege waffle:

A divider, a fermentation chamber, a machine for transferring automatically the lumps of paste in the irons, the oven, a robot for the removal of waffles after the cooking, cooling bands.

Automatic line for all kind of products:

A divider/injector, the oven, a removal system, cooling bands.

Every production line is adapted to the customers’ needs.

Tunnel Oven

The tunnel ovens allow the cooking of any kind of pastry and are suitable for products like waffles, galettes, pancakes, hotcakes, crackers, etc…They are destined to the production of big capacities. This kind of oven is available in a large range of width and length of cooking allowing a productivity going to 150 000 pieces per hour according the cooking time and the size of the product.

TV Oven

They are mainly destined to the cooking of soft waffles. This kind of oven is provided with a very precise proportioning system of pastry with a removing system to take out the waffles after their cooking.

TH Oven

The TH Oven offers the possibility to make several different productions thanks to the interchangeable character of the waffle irons. This oven produces at least 1000 waffles per hour. It can also be equipped with an automatic injection device and with an extraction system. This oven exists in a standard version of 20, 24, 30 or 36 waffle irons.

TV-8 Oven

The new semi-automated oven TV-8 is ideal for small productions. Please find below some technical features of this oven:

- Automatic opening and closing of the waffle irons

- Automatic rotation of the waffle irons

- 8 waffle irons 320 x 240 mm

- Production capacity: from 600 to 900 waffles/hour, depending on the type of waffle

- Cooking time: 3 minutes (setable)

- Natural Gaz of GPL

- Power: 220V - 10A

- Oven weight and dimensions: 500 kg - 120x80x160 cm

Fermentation chambers

We create fermentation chambers according to the needs of the customer. They are equipped with rotating shelves in stainless steel and are available in all sizes.

Conveyor belts and/or cooling bands

We manufacture straight-line, curved or spiral conveyors of all size according to the needs of the customer.

Accessories

- Injection device for all kind of waffles;

- Robot destined to the automatic removal of waffles;

- Automatic brushes;

- Cleaning system;

- Lubrication system of the waffle irons.

Contact Information

Acemal nv

61 av Thomas Edison

1402 Thines (Nivelles)

Tel: +3223566782

Fax: +3267443203

e-mail : acemal@acemal.com

website : www.acemal.com