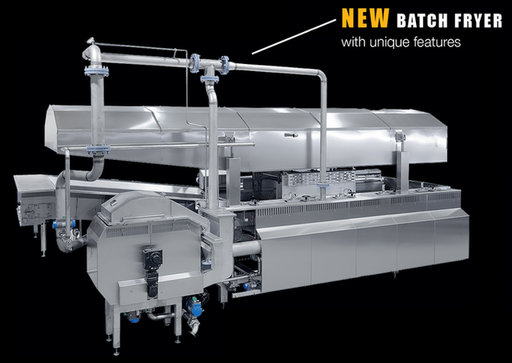

BEST FOR BATCH FRIED CHIPS

WWW.ROSENQVISTS.COM

FEATURES

- Continuous oil filtration

- No internal piping – External heating

- Adjustable temperature curve along the frying cycle

- Quick and complete discharge between batches

- Extended production time between

- Cleaning stops

Superior Frying with THE star wheel fryer

Developing and Designing French Fry lines for more than 40 years

Do you have

Any special

Pellets frying needs?

THE PROCESS

UNIQUE PELLET FRYING SOLUTION

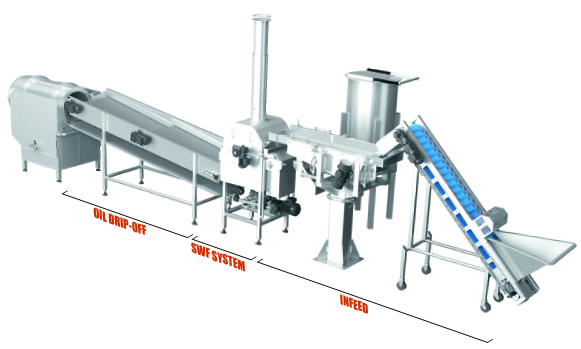

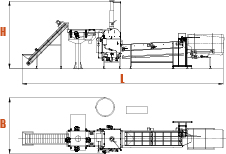

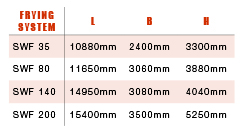

The patented Star Wheel Fryer (SWF) provides gentle handling and uniform frying of many different pellet snacks from rings to 3-dimensional products. With the lowest total oil volume of any pellet fryer on the market, the patented Star Wheel fryer is available in three sizes with outputs from 100-750 kg/h.

PERFORMANCE

The SWF system has very low total oil volume with the smallest model containing only 87 liters for a capacity of up to 150kg/h. The low oil volume equates to exceptional turnover rates at just 2-4 hours optimizing product quality and extending shelf-life. And, for added convenience, the oil level of the fryer is automatically controlled.

OPERATIONS

The SWF system is designed to give you maximum flexibility in the production of top-quality snacks. From rings to more complex 3-dimensional snacks, the SWF easily and efficiently handles a wide variety of pellet products.

With adjustable frying time from 8-40 seconds the patented and state of the art frying wheel design, the pellets will be uniformly fried.

An advanced controller maintains and controls oil temperature. The infeed system consists of an incline elevator to handle the most fragile of products and a vibratory conveyor with built in screen to remove small pieces. After the fryer the fried product passes an oil-drip-off belt prior to the seasoning process.

The installation is simple with pre-assembly of all pipes between oil supply tank, level control and fryer. The SWF system is designed with easy operation and CIP cleaning. The exhaust stack is removed allowing easy access to the frying wheel which is lifted via a motor-driven lifting system.

QUALITY GUARANTEED

Efficient Oil Management

- Lowest oil volume of any pellet fryer on market

- Quick oil turnover rates—just 2-4 hours

Optimum Product Quality

- Adjustable frying time from 8-40 seconds

- Precise and controlled frying time due to patented frying wheel

FRYING potato chips

developing and

designing frying

system for more

than 45 year

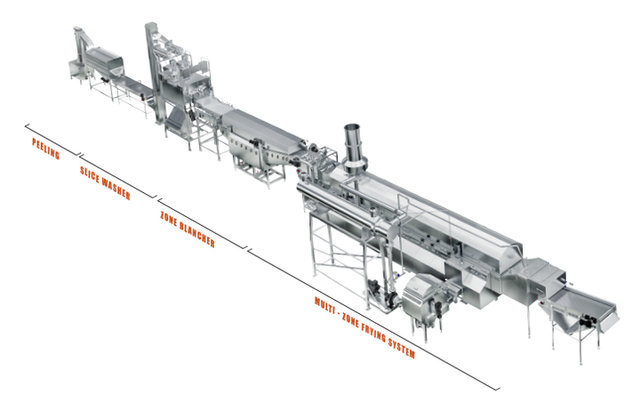

THE PROCESS

DEVELOPING AND DESIGNING POTATO CHIPS LINES FOR MORE THAN 45 YEARS

Rosenqvists Food Technologies has extensive knowledge of the potato as raw material and how to design an effective process. We combine the latest technologies using computer simulation programs and build efficient and reliable process equipment. We take responsibility for design, manufacture and installation. We will commission the line and make sure that your staff get professional training in maintenance and process control.

STEP 1: PREPARATION

Potatoes are destoned and washed in the Rosenqvists Vertical Screw Destoner. For more difficult soil conditions, we recommend our Cyclone Destoner. The Continuous Abrasive Peeler peels the potatoes gently with an even and accurate result.

STEP 2 : SLICE WASHING

After slicing, the starch on the surface of the slices needs to be washed away. The Rosenqvists Slice Washer uses minimum amount of water to gently clean the potato slices. Small potato particles are effectively removed from the product flow.

STEP 3 : BLANCHING

If your raw material contains higher levels of sugar, the blancher will leak out/reduce the sugar level so that a golden chip can still be produced. The unique Zone Blancher separates every single slice for optimum and even blanching result. The temperature, set in three zones and the paddle belt assure a controlled and exact blanching effect. The bottom belt design allows to run the blancher without water when processing chips of low-sugar level potatoes.

STEP 4 : MULTI- ZONE FRYING

The critical phase in the potato chip process is the frying phase. With controlled oil flows and Multi-Zone design, the Rosenqvists frying system will be frying the potato slices to perfect texture, bite and colour. Low total oil volume, special design hood, etc. guarantees the best final product quality.

QUALITY GUARANTEED

Our strength is in our core competence: process lines for the production of chips. By customising our systems, we create the right conditions for you to succeed with your business. Let our competence be your success.

FRYING SYSTEM FOR NUTS

developing and

designing frying

system for more

than 45 years

THE PROCESS

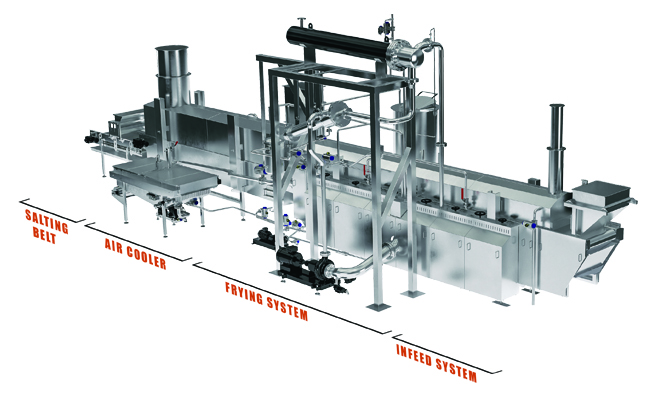

VERSATILE PRODUCTION RANGE

The Rosenqvists nut frying systems are suitable for all types of nuts and seeds. The fryer is excellent for coated nuts. Depending on the final product, the frying system is equipped with the suitable type of belt, oil filtration system, and possible need of a top submerger belt to ensure optimal production and final product quality.

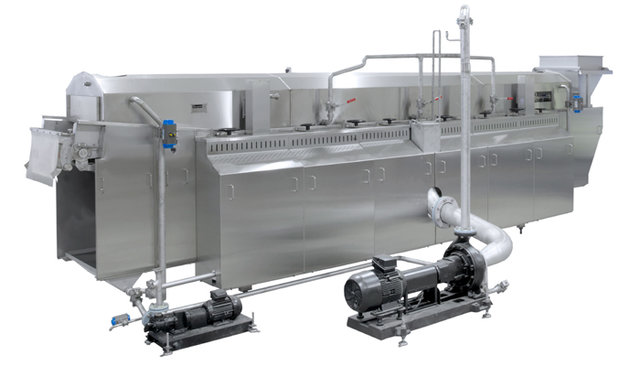

THE FRYING SYSTEM

The fryer uses an external heating system which reduces the total oil volume and ensures that the vegetable oil is not overheated. The fryer is equipped with a CIP (Clean-In-Place ) washing system, and with no tubing inside the frying pan, cleaning is made easy.

The vegetable oil is cleaned continuously in the external filter system, and is heated by the tube heat exchanger using thermo-oil as heating media. With multiple inlets and outlets for the frying oil, the desired temperature profile along the fryer pan can be set to match each product. The low total oil volume in the complete frying system gives shorter Oil-Turn-Over-Time Rates than traditional fryers.

After frying, the nuts are cooled to the required final temperature in the ambient air cooler. Rosenqvists also supplies the infeed system and salt & oil application systems.

Fryer for peanuts

QUALITY GUARANTEED

HEATED BY THERMO-OIL

External Heat Exchanger

No internal tubing in frying pan

MULTIPLE OIL INLETS-AND OUTLETS

Creating accurate temperature curve

Versatile frying, ”Labyrinth” design ensure even flow

TEMPERATURE SENSORS

Accurate temperature control

OIL LEVEL CONTROL

Accurate level in fryer

Protection against overflow

CONTINUOUS OIL FILTRATION

Longer production time

Less down time for cleaning

SCRAPER INSIDE FRYING PAN

Longer production time between cleaning

DOUBLE DRIVE SYSTEM

Ensures even and flawless belt movement