COMPANY INSIGHT

Taking a big bite out of the food, feed, beverage sectors with BUCHI solutions

Here is some food for thought. BUCHI has decades of experience in using analytical methods to help you outperform yourself and all others in the food, feed and beverage sectors. Apply the power of innovative chemistry for faster, more cost-efficient processes and higher quality end products that impress your customers.

An established leader in food and feed analytics

For more than 75 years, BUCHI has been a global leading solutions provider in laboratory technology for R&D, quality control and production purposes. The company serves the food, feed and beverage industries by offering proven solutions for laboratory, industrial and parallel evaporation, spray drying, encapsulating, melting point, freeze drying, preparative chromatography, extraction, distillation and digestion, and near infrared spectroscopy.

BUCHI excels at offering exceptional services that are innovative, efficient, convenient and precisely tailored to individual customer needs. With a global network of subsidiaries, support centres, and distribution partners, BUCHI consistently delivers “quality in your hands” to customers in any corner of the world.

Food trays and baking molds made from Genuine Vegetable parchment are biodegradable and home compostable.

Proven solutions for the food and feed industries

BUCHI offers unmatched expertise in addressing analytical challenges in the food, feed and beverage industries. The company can help drastically increase the efficiency of product processing and development with classical reference methods such as the Kjeldahl method, solutions for classical determination of fat, near infrared (NIR) spectroscopy for real-time food analysis, as well as spray draying and encapsulation for visualization of production processes.

Our products for nitrogen and protein determination, drying, fat extraction, raw material identification, as well as analysis of food components, additives, contaminants and residues, facilitate the optimization of the entire value chain from the R&D and QC laboratories to the production lines.

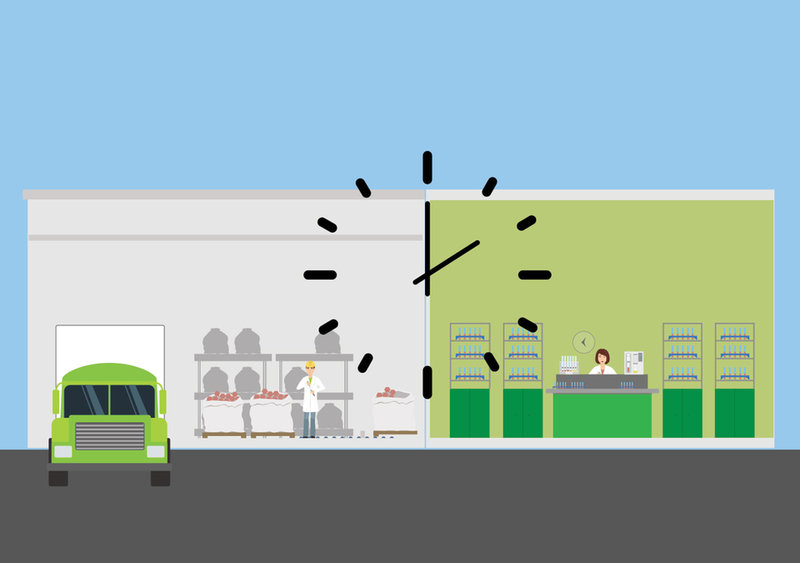

Save time during incoming goods inspections

Use NIR to measure useful sample properties such as fat, protein and moisture. Rely on a modern system for simultaneous real-time analysis of several parameters, minimal to no sample preparation and non-destructive measurements. Use smartly developed NIR equipment to significantly speed up decision processes based on QC data, detect costly deviations faster, increase the volume of incoming goods that can be inspected simultaneously and take advantage of automated quality measurements at various points of the production chain.

Perform protein determination using cutting-edge technology for reference methods, such as the Kjeldahl method. Save time by using a system with efficient distillation units that can shorten distillation times, increase sample throughput thanks to parallel digestion and decrease processing times with faster heating and cooling at the digestion stage. For classical extraction processes, such as total fat extraction, take advantage of powerful extractors that are fast and easy to operate to decrease extraction duration and increase process efficiency.

Discover how you can save time with our solutions and download Volume 1 of the Food Process Analytics Guidebook here

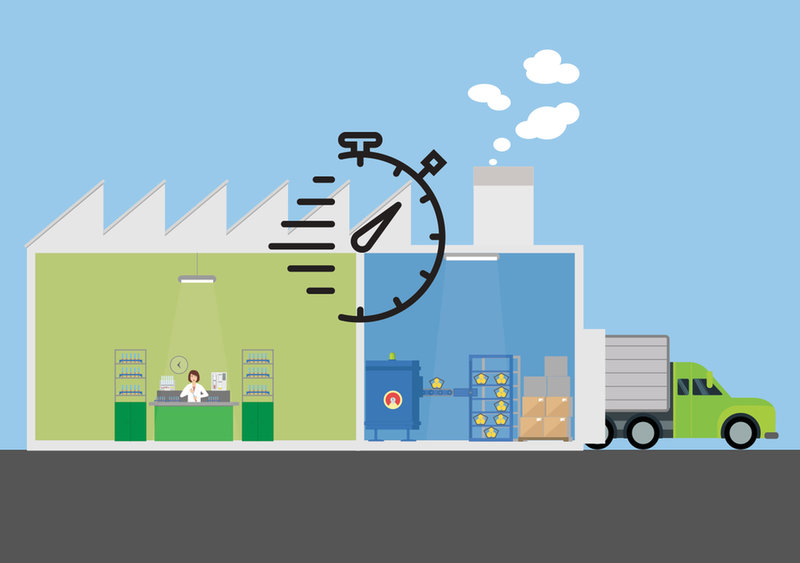

Improve cost-efficiency of process monitoring

Using NIR analysis for process control offers substantial savings. Costs of labor, reagents and lab equipment are considerably lower compared to traditional analytical methods. Real-time continuous measurements on-line or in-line and our robust at-line solutions offer direct process control and quick elimination of deviations that could otherwise expensively propagate in downstream processes. Apply NIR analysis for applications such as moisture control, extraction monitoring, protein addition and monitoring of mixing processes to avoid unnecessary step repetitions, run production closer to specified targets, increase energy efficiency and improve consistency of final product quality.

Discover how you can save money with our solutions and download Volume 2 of the Food Process Analytics Guidebook here

Optimized final goods inspection processes

Quantification of protein, fat and other ingredients using Kjeldahl, extraction and NIR techniques should be carried out on modern systems with automated capabilities. Such instruments support efforts to continuously increase sample throughout, ease-of-use, sensitivity and application scope of the process. Automated data transfer ensures data integrity is maintained, increases work efficiency and reduces labor costs. Electronically stored data supports high data security, enables flexible exchange of results and makes full traceability possible. Intelligent system software facilitates downstream data evaluation and report generation for quick and reliable final analysis of results.

Discover how you can optimize final foods inspection with our solutions and download Volume 3 of the Food Process Analytics Guidebook here

For more information contact us at:

BÜCHI Labortechnik AG

Meierseggstr. 40, Postfach

CH-9230 Flawil 1 - Switzerland

T +41 (0)71 394 63 63

F +41 (0)71 394 64 64

Website: www.buchi.com

E-Mail: marketing@buchi.com