COMPANY INSIGHT

Sponsored by allfo and allvac

Your specialist in barrier packaging

allfo Vakuumverpackungen is the European market leader for high-quality vacuum bags. The wide assortment, which is available in various sizes and film thicknesses, ranges from side-seal bags, shrink bags and tubular bags to cook-in bags, stand-up pouches and multilayer bags.

allvac Folien produces thermoformable barrier films based on polyethylene and polyamide. Particularly used for the packaging of perishable foodstuffs, they also form the prime-quality basis for the bag production of our sister company allfo.

The renowned bag specialist develops and produces individual packaging solutions, according to customer requirements. Flexible and fast production guarantees speedy delivery and maximum security of supply for the customer. Particularly the food industry benefits from the bag solutions for packaging meat, meat products and sausages, corn and sous-vide dishes. allfo is equally suited for non-food applications, such as in pharmaceuticals, cosmetics, chemicals and the packaging of technical products.

Carefully selected, high-quality raw materials from innovative, renowned suppliers and constant further development of the film construction as well as production processes result in first-class films, which allvac manufactures. All film types have one thing in common: they guarantee an optimal and aesthetic product presentation and ensure smooth processing due to their excellent machinability.

The production of allvac is based on modern machinery

The production of our thermoforming barrier films is implemented in two different processes: Blown film extrusion and cast film extrusion. The choice of process depends on the film properties required for the final application, such as film thickness and strength, thermo-formability or reverse shrinkage characteristics. allvac's response to the trend towards multilayer systems is the coextrusion line, which has been integrated in production recently, allowing the manufacture of composite films with up to 11 layers in accordance with the latest formulas. With its modern and sustainable machinery, allvac can thus cover the entire spectrum of barrier films for packaging in food production.

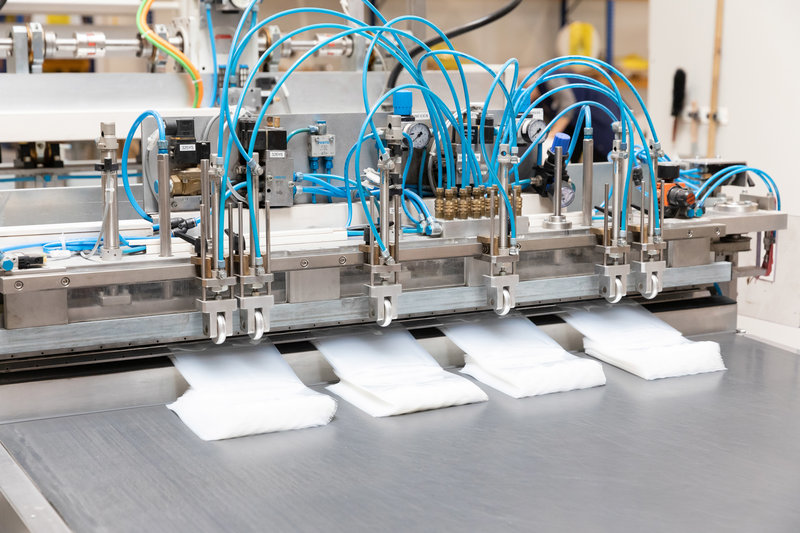

allfo: Smooth confectioning of a wide variety of bags

Whether you need side seal bags, tubular bags, multilayer bags, shrink bags, cook-in bags, stand-up pouches, textured bags or printed bags – we always keep a large number of the most common sizes in stock, pallet by pallet, in order to ensure short delivery times for your benefit. Ultimately, your delivery will also depend on our speed in confectioning.

In order to guarantee a high level of precision, quality and finishing of your bags in the future, we gladly and extensively invest in our state-of-the-art machinery. Our experience and know-how, our motivated employees and our high-performance machines in the confectioning department not only produce standard products in large quantities. Niche products with special features are also bundled and packed here in boxes.

Ecological, economic and social

Film packaging protects. It ensures that products withstand even longer transport routes undamaged. It increases the shelf life of food while enhancing its appetising appearance at the point of sale. Film packaging reduces the amount of food that has to be disposed of due to spoilage. It makes an important contribution to sustainability including all aspects mentioned.

Environmentally compatible materials, but also those that are recyclable, i.e. can be returned to the production process, are concrete approaches that have already reached market maturity. The motive is to conserve and save fossil raw materials.