STEEL BELTS FOR CONTINUOUS FOOD PROCESSING

IPCO is the world’s largest supplier of solid and perforated steel belts to the food processing industry, and we supply a range of steel grades, thicknesses, widths and lengths to suit any process or product type.

More resistant to damage by corrosion, abrasion or impact than any other belt type, a stainless steel conveyor represents outstanding long-term value and delivers an excellent return on investment.

But the quality of greatest value to the food industry is its ease of cleaning: an IPCO stainless steel belt can be sanitised in whichever way is most appropriate: hot water, pressure, brushes, detergents, or chemicals.

Solid and perforated steel belts for bake ovens

Flat, smooth and stable, IPCO bake oven belts deliver reliable performance, optimum bake quality and exceptional versatility, and are used for products as diverse as biscuits, brownies, crackers, pastries, energy bars, part-baked bread, sponges, all-butter cookies, pizza bases and more.

- Excellent heat transfer

- Stable operation for a consistent bake

- Low maintenance requirements

- Outstanding durability for a working life of 20+ years

- Belts widths from 800-3500 mm for maximum productivity

- Lighter than wire mesh so more economical to heat

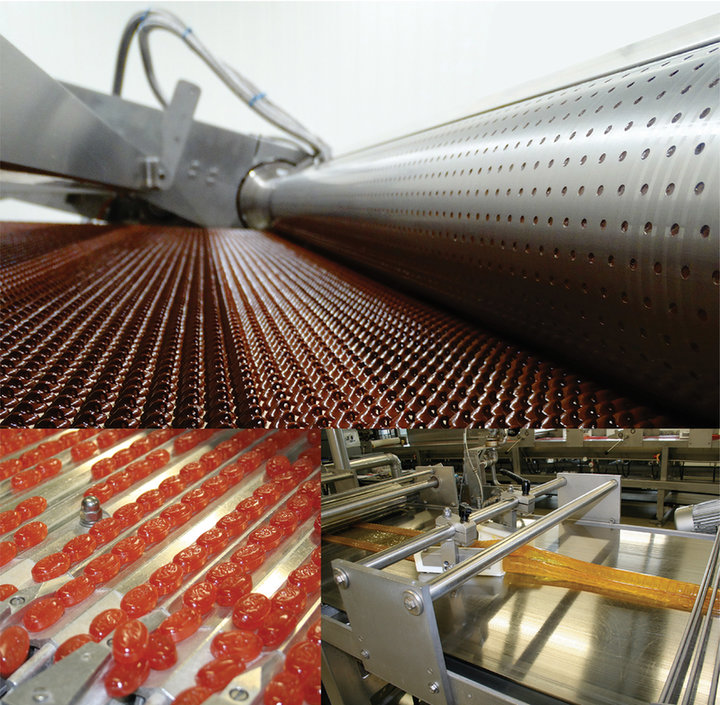

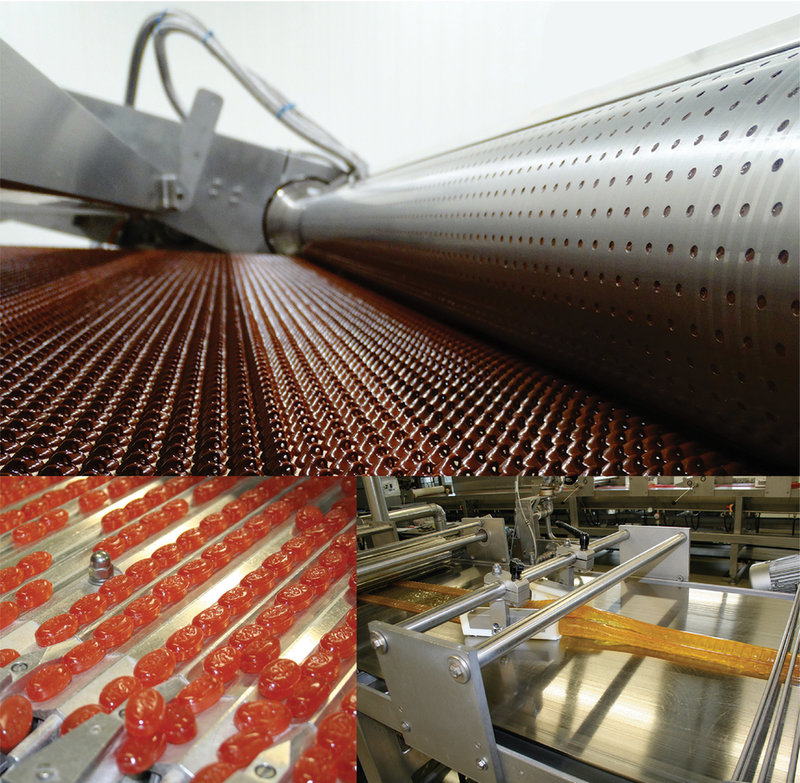

Controlled cooling, forming and pastillation

IPCO steel belts are widely used for cooling and solidifying food products into a form suitable for easy handling, packaging or subsequent reprocessing. Applications include caramel, gum base, gelatine, hard melt candy, nougat, liquorice, nut brittle, cooked/steamed vegetables and more.

Our steel belts are also used extensively in the chocolate industry for pastillation and other forming processes.

- Outstanding thermal qualities

- Controlled and efficient cooling and solidification

- Consistent, high quality end product

- Quick and easy cleaning for maximum hygiene

- Ideal for chocolate and confectionery processing

Continuous food processing – what’s your application?

IPCO steel belt conveyors are at the heart of all types of continuous food processing systems. We have the process understanding to tailor a service to each customer’s needs, from belt-only supply through to close partnerships with machine builders/OEMs.

- Drying – perforated steel belts for multi-stage fruit and vegetable dryers.

- Freezing – e.g. meat, shellfish, instant coffee, etc.

- Meat – Easy sanitizing of deboning/cutting lines.

- Sorting – e.g. tomato sorting and selecting.

- Steam cooking – Reliable performance in a hot and humid environment.

- Thin film casting – Accurate production of extremely thin edible films.