Company Insight

Sponsored by Avista, a Global Brand of Kurita

Avista Impact Study

Avista Membrane Treatment Solutions reduce membrane system operation and maintenance costs for food & beverage plants.

Image: copyright

A

t Kurita, we believe creating sustainable membrane treatment solutions that increase water production and reduce environmental impact is critical to meet the food and beverage industry’s rising demand for quality water.

We have a new solution. Avista™, a global brand of Kurita.

Clck to enlarge

We will explore an impact study that demonstrates how Avista Membrane Treatment Solutions helped a Beverage plant uncover and solve the drivers for high operational costs and high membrane replacement rate.

Over the span of ten years, this beverage plant experienced a significant operational cost increase for their RO system due to a lack of maintenance, operator training and changing water quality.

A detailed Avista audit of the original system design including pretreatment, water quality, particle count, turbidity testing as well as the results of a membrane autopsy results helped to identify the source of membrane fouling. Cost comparison between the current operation and the past 10 years will be shown in the Impact conclusions. This tactical planning approach can be applied to help other food and beverage reverse osmosis treatment plants reduce their operational costs while also increasing membrane life.

We will study cost increase causes, including:

- Energy cost increasing with the increase of feed pressure

- Weekly RO CIPs

- Daily cartridge filter replacement

- Annual RO membrane replacement

System Review: Technical support to troubleshoot process challenges.

Understanding the system design

First step in the process is to evaluate the current system design. Follow the diagram to see what we learned.

Clck to enlarge

The data agreed with the plant suspicions

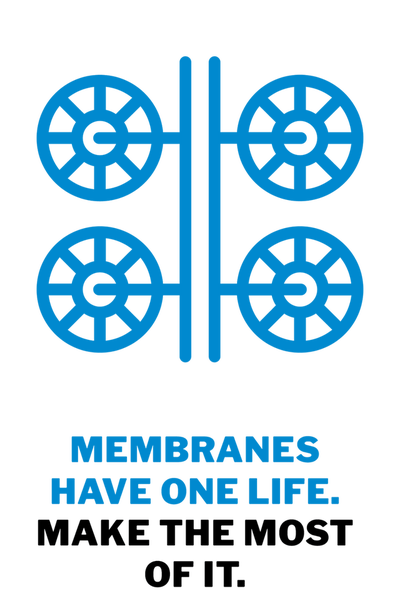

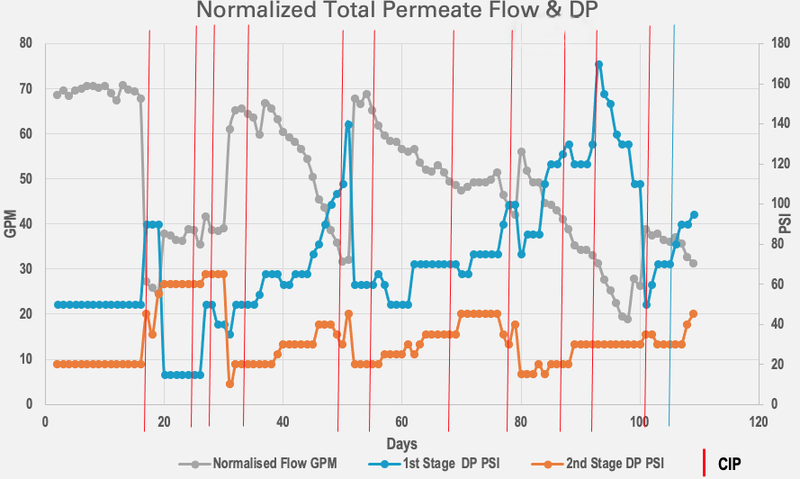

Based on their own evaluation, the Beverage plant’s management team had a suspicion of what what the problem was – insufficient removal of metals by the green sand filters. The normalized permeate flow data was the overall flow rate of the 1st Pass RO. The disadvantage of only looking at the total permeate flow is that it was not possible to tell whether Stage 2 performance had been compromised.

The CIP efforts did not appear to help with restoring the permeate flow rate or the DP back to baseline and also did not provide sustainable performance over time.

Diagnose: Laboratory services to analyse foulant or scaling.

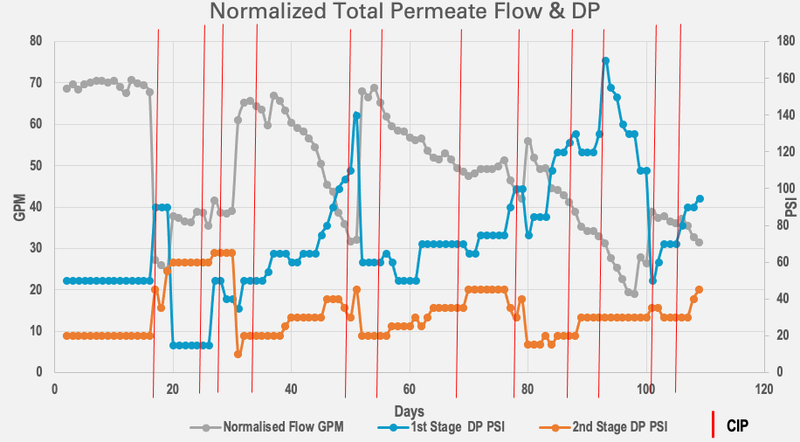

Avista cartridge filter autopsy result

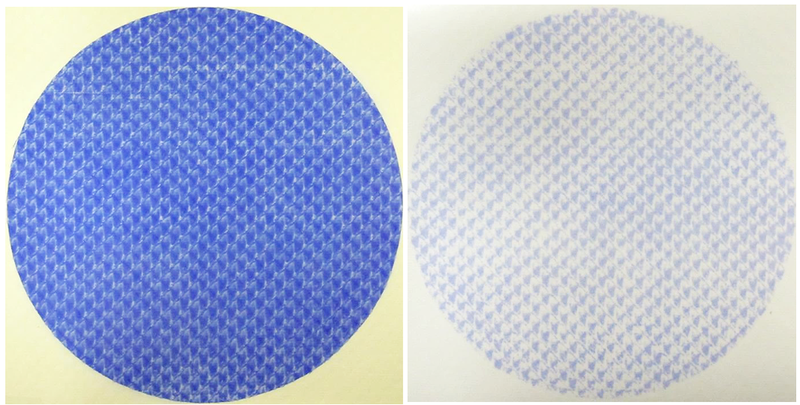

A walkthrough of the plant revealed black cartridge filters, which had just been replaced after being online for only three days.

After confirming the material as primarily manganese, the next step was to determine how it was bypassing the GS filters and fouling the membranes.

Easy but effective troubleshooting

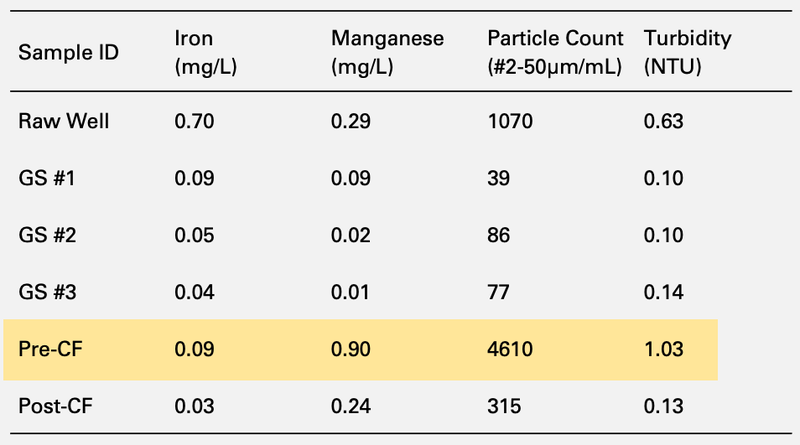

Additionally, a profile of iron, manganese, particle count and turbidity removal throughout the system was performed to determine the source of the manganese bypass. The site was surprised to see that the GS filters were achieving efficient removal of iron, manganese and particulates. However, manganese levels increased above the raw well values before the cartridge filter. The primary explanations for this result include slugs of manganese coming into the system that were not observed at the time of sampling or issues within the holding tank.

This finding prompted the operators to inspect the holding tank.

Was the holding tank to blame?

The beverage plant believed that the manganese in the tank was likely a result of small bypasses throughout the years accumulating, which then sloughed off the tank periodically, fouling the cartridge filters and RO. After the tank was cleaned, it was believed that the cause of the system fouling was resolved.

The RO system was cleaned with a specialty cleaner targeting metals. The water production and DP were restored but the permeate conductivity was too high.

Clck to enlarge

Taking extra steps is key in troubleshooting

The decision was made to replace the membranes in the first pass because they did not provide the needed quality. Loss in membrane integrity historically influenced the replacement of the first pass membranes; however, the site did not know the cause for the decrease in permeate quality.

A lead and tail membrane were chosen for dissection and an Avista Membrane Autopsy to troubleshoot the loss in element rejection.

Stage 1, lead position

Dye Test showing membrane oxidation damage:

Stage 2, tail position

Dye Test showing membrane oxidation damage:

High-resolution imaging technique to

identify inorganic foulants.

Historical data revealed the mystery damage

Membrane autopsies of the lead and tail elements showed signs of membrane oxidation. Back calculating of the KMnO4 dose surprisingly showed that it was being over-dosed. This finding could explain the amount of manganese fouling found in the holding tanks and the membrane damage since KMnO4 is an oxidizer. After thorough review of historical maintenance records, it was discovered that the KMnO4 dose remained consistent regardless of how many of the GS filers were operational. At times, only one GS filter was running therefore KMnO4 was overdosed, causing membrane damage.

It was determined that the site was over dosing at 0.55 ppm, when 1.27 ppm was required.

Protecting the membranes from oxidation

The plant was able to change the dosing procedures of KMnO4 to account for the number of filters online by installing a flow-paced injection pump. But to be on the safe side the plant management decided to opt in to adding a reducing agent to neutralize any residual KMnO4 oxidizer.

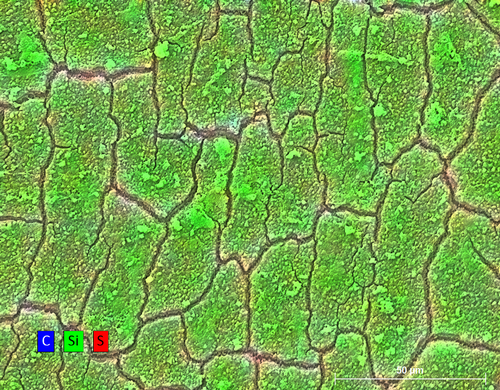

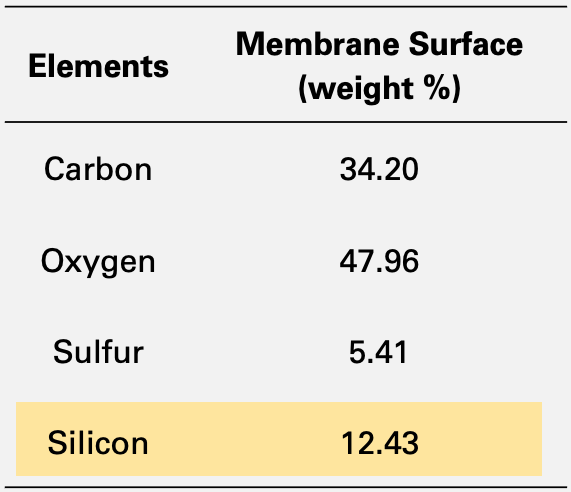

Unexpected silica scale on the tail membrane

The tail element autopsy identified silica scale. The plant operators did not expect having problems with scaling because an antiscalant was being dosed. As the system did not have flow meters on every stage, the normalized permeate flow data was the overall flow rate of the 1st Pass RO. The disadvantage of only looking at the total permeate flow is that it was not possible to tell whether Stage 2 performance had been compromised.

The autopsy results showed that the antiscalant used was not effective in inhibiting silica scale formation.

Apply & Monitor: Chemical application support to assure the best results

Protecting the membranes from scale

The antiscalant used at the plant prior to the audit was not a targeted formulation but a generic product used to disperse ions in solution.

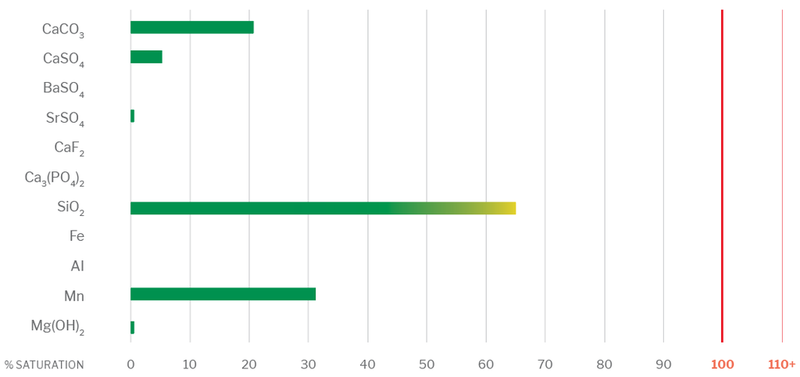

Based on the data collected from the full mineral analysis, it was apparent that using a specialized antiscalant that would target silica would offer better results.

Evaluating the current water analysis

Saturation indices at 75% recovery

Optimizing the system recovery

Further inspection of the RO unit revealed disconnected pressure vessels in both stages of the first pass.

By reconfiguring the array of the system to be 6:3, the design software determined that the system recovery could be increased to 75% without any hydraulic issues.

Click to enlarge

Impact = Cost reduction:

Creative Chemistry. Smart Solutions.

Summary

The Beverage Plant’s system optimization was achieved by cleaning the holding tank, implementing a proper dose of sodium metabisulfite (SMBS) to offset potassium permanganate oxidation and changing the antiscalant to a silica-inhibiting antiscalant. Further system improvements were gained by optimizing the recovery of the system. Improved recoveries were made possible by implementing a silica scale inhibitor at a lower dose rate than the previous scale inhibitor.

- Site suspected insufficient removal of metals by the GS filters

- Incomplete normalized data supported site suspicions

- Easy but effective methods used to identify actual source of fouling

- Holding tank severely fouled with years worth of GS breakthrough due to oxidizer underdosing

- Membrane oxidation damage due to occasional oxidizer overdosing

- Unexpected silica scale fixed by using targeted antiscalant

- System recovery optimized by modifying system design

Download technical paper

For an in-depth view of this impact study, download our technical paper.

Download Brochure

Contact details

Kurita UK. Ltd.

Avista™ | Centre of Excellence

13 Nasmyth Square, Houstoun Industrial Estate

Livingston, EH54 5GG

United Kingdom

Phone: +44 0 131 449 6677

Fax: +44 0 131 449 5599