Packaging Films, Sustainability & Carbon Footprint

The history of Innovia Films (Innovia) spans nearly 90 years. During which time, the company has advanced its technical expertise, expanded its global reach through acquisition and natural growth and continued to develop, refine and launch new products into the marketplace.

more

Today Innovia is a major producer of highly differentiated speciality polypropylene films offering products produced using ‘Bubble’, Stenter and Cast manufacturing processes. It holds a leading global position in the markets for high performance food packaging, label and security films.

more

Innovia employs >1400 people worldwide and has production sites in Australia, Belgium, Germany, Poland, Mexico and the United Kingdom, with a total capacity of 218,000 tonnes. The company is focused on high-quality value-added products, strong customer relationships, Research & Development, and excellent service.

NEXT PAGE

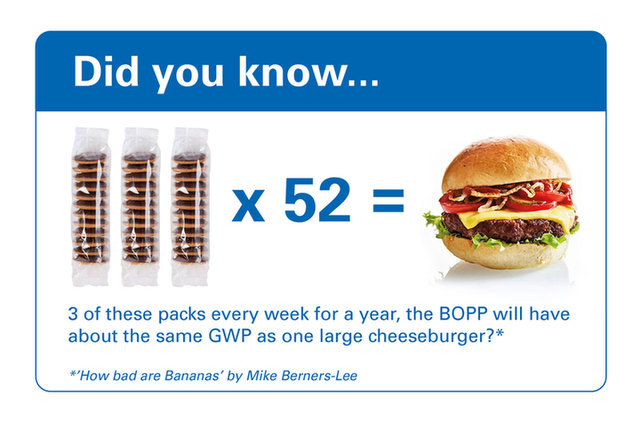

The main challenge today is the current consumer view that plastic packaging is bad and unrecyclable. They overlook the fact that these films protect and preserve the products they wrap. Flexible packaging and in particular low-density materials such as Biaxially Oriented Polypropylene (BOPP) are the most resource efficient packaging option because of their lightweight.

Sustainability in packaging is important, globally it has been recognized that we need to reduce our carbon emissions to help stop global warming. Food waste is a major contributor to carbon emissions, making packaging vital to extend their shelf life. This is primarily done using high barrier packaging.

The UN has stated that if food waste greenhouse gas emissions were a country, it would be the third largest in the world.

Carbon Footprint

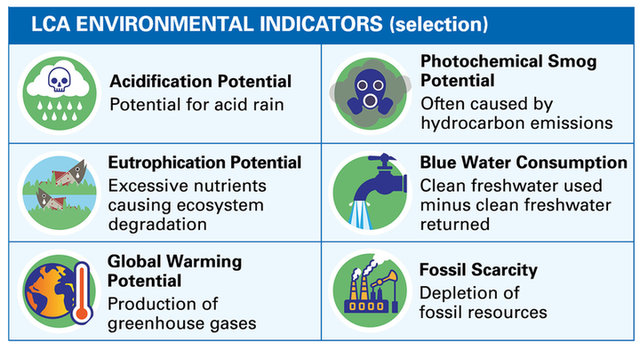

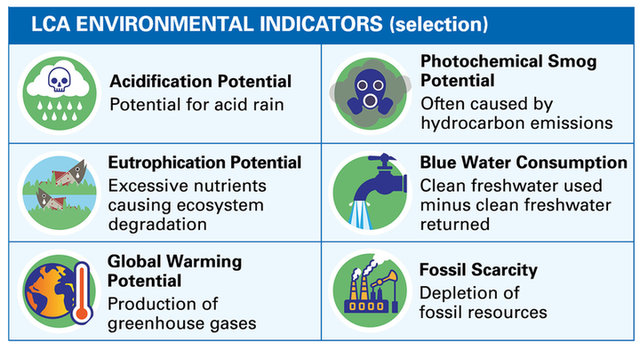

Innovia considers that the war is not on plastic, but on carbon footprint and moved to develop a strategy that fits the environmental demands of the 21st Century. Life Cycle Analysis (LCA) has become an increasingly important part of Innovia’s new product development focus. They have developed their own in-house LCA system and are able to produce actual data on products to show how the carbon footprint of a pack can be reduced.

With so many big brands such as Nestle, committing to reducing their carbon footprint by 2030 the obvious route is to use Life Cycle Analysis to identify the most appropriate materials to use for their packaging requirements.

Brands need to be careful about moving to other alternative forms of packaging. It is well known that other packaging formats can increase the carbon footprint of the product and be detrimental to other environmental indicators.

Innovia believes that ultimately recycling of flexible films will increase which will provide the needed polymer for a truly circular economy which will ensure that the carbon footprint of future products and the use of fossil resources will continue to reduce.

Improving Recyclability

Innovia has developed two new BOPP film ranges aimed at improving the recyclability of pack structures and to reduce carbon footprints.

The Propafilm™ Strata range are high barrier EVOH mono multilayer films that can be used as stand-alone packaging or within laminate structures such as pouches to make them easier to recycle. The most recent launch in this product range is Propafilm™ Strata SLF a high-speed barrier packaging film for horizontal form-fill-seal applications. All Strata products are chlorine free.

The other is our Encore highly functional sustainable film range. These films are manufactured from renewable non-food based raw materials, helping to reduce the use of fossil-based virgin raw materials. They can be manufactured to reduce the carbon footprint of the film or to be fully carbon neutral (cradle to gate). The renewable polymer for Encore is managed through ISCC PLUS chain of custody. They are suitable for use in all market segments currently using BOPP films.

Chemical recycling of polypropylene is a rapidly developing technology which reduces the use of fossil raw materials and is food contact compliant, while maintaining all the properties of fossil-based films. However, from a GWP perspective, it does not have as good a carbon footprint as mechanical recycled polypropylene.

Innovia has product options for BOPP flexible films with both chemically recycled or mechanically recycled polymers under the Encore range.

Working with Interseroh, an Independent German recycling and consulting company, we have confirmed the recyclability of all our uncoated, acrylic coated, Strata and Encore range of BOPP films. All have achieved the ‘Made for recycling’ certification.

This certification provides us with independent validation that our polypropylene films are fully recyclable and can be classified as ‘recycle ready’, or recyclable in countries which have the infrastructure to recycle polypropylene.

Committed

Innovia are active members of the British Plastic Federation and is a stakeholder in CEFLEX, a collaborative initiative bringing the entire value chain of flexible packaging together to tackle the complex technical and business barriers to a circular economy.

Their parent company CCL Industries Inc have signed the New Plastics Economy Global Commitment led by the Ellen MacArthur Foundation. Launched in 2010, this charitable organisation is dedicated to accelerating the transition to a circular economy.

Carbon Footprint

Innovia considers that the war is not on plastic, but on carbon footprint and moved to develop a strategy that fits the environmental demands of the 21st Century. Life Cycle Analysis (LCA) has become an increasingly important part of Innovia’s new product development focus. They have developed their own in-house LCA system and are able to produce actual data on products to show how the carbon footprint of a pack can be reduced.

With so many big brands such as Nestle, committing to reducing their carbon footprint by 2030 the obvious route is to use Life Cycle Analysis to identify the most appropriate materials to use for their packaging requirements.

Brands need to be careful about moving to other alternative forms of packaging. It is well known that other packaging formats can increase the carbon footprint of the product and be detrimental to other environmental indicators.

Innovia believes that ultimately recycling of flexible films will increase which will provide the needed polymer for a truly circular economy which will ensure that the carbon footprint of future products and the use of fossil resources will continue to reduce.

Improving Recyclability

Innovia has developed two new BOPP film ranges aimed at improving the recyclability of pack structures and to reduce carbon footprints.

The Propafilm™ Strata range are high barrier EVOH mono multilayer films that can be used as stand-alone packaging or within laminate structures such as pouches to make them easier to recycle. The most recent launch in this product range is Propafilm™ Strata SLF a high-speed barrier packaging film for horizontal form-fill-seal applications. All Strata products are chlorine free.

Brands need to be careful about moving to other alternative forms of packaging. It is well known that other packaging formats can increase the carbon footprint of the product and be detrimental to other environmental indicators.

Innovia believes that ultimately recycling of flexible films will increase which will provide the needed polymer for a truly circular economy which will ensure that the carbon footprint of future products and the use of fossil resources will continue to reduce.

The other is our Encore highly functional sustainable film range. These films are manufactured from renewable non-food based raw materials, helping to reduce the use of fossil-based virgin raw materials. They can be manufactured to reduce the carbon footprint of the film or to be fully carbon neutral (cradle to gate). The renewable polymer for Encore is managed through ISCC PLUS chain of custody. They are suitable for use in all market segments currently using BOPP films.

Chemical recycling of polypropylene is a rapidly developing technology which reduces the use of fossil raw materials and is food contact compliant, while maintaining all the properties of fossil-based films. However, from a GWP perspective, it does not have as good a carbon footprint as mechanical recycled polypropylene.

Innovia has product options for BOPP flexible films with both chemically recycled or mechanically recycled polymers under the Encore range.

Working with Interseroh, an Independent German recycling and consulting company, we have confirmed the recyclability of all our uncoated, acrylic coated, Strata and Encore range of BOPP films. All have achieved the ‘Made for recycling’ certification. This certification provides us with independent validation that our polypropylene films are fully recyclable and can be classified as ‘recycle ready’, or recyclable in countries which have the infrastructure to recycle polypropylene.

Committed

Innovia are active members of the British Plastic Federation and is a stakeholder in CEFLEX, a collaborative initiative bringing the entire value chain of flexible packaging together to tackle the complex technical and business barriers to a circular economy.

Their parent company CCL Industries Inc have signed the New Plastics Economy Global Commitment led by the Ellen MacArthur Foundation. Launched in 2010, this charitable organisation is dedicated to accelerating the transition to a circular economy.